Lead Acid battery is touted as the cheapest battery available. In fact, Lead Acid is the family name for a collection of closely related battery types, from simple vented/flooded to advaned Valve Regulated ones. Depending upon the type of usage, there are shallow and deep cycle batteries. Typical examples of shallow cycle batteries are the ordinary car starter batteries, where as deep cycle batteries are used for prolonged deep discharge operations like electric propulsion, UPS etc. For a comparison, some reasonable Deep Cycle flooded batteries are available for around $120 per name plate KWh. This “lowest cost” has given a lot of advantage for Lead Acid batteries in renewable energy applications. But before getting deep into the deep cycle lead acid batteries there are a lot of interesting facts to consider.

The Fine Prints

Both capacity and the state of charge depend heavily upon a factor named Vpc which is nothing but Voltage per Cell. Normally all standard battery manufacturers quote their capacity to 1.75 Vpc with a discharge time of 20 hours. In simple language, it is the capacity until the voltage of the cell reaches 1.75V with a discharge period of 20 hours. 1.75 V is considered as 0% State of Charge. As Depth of Discharge (DoD) is just the opposite of State of Charge, it is nothing but 100% Depth of Discharge. But discharging up to that level puts a lot of stress on the battery, so that, the battery could only handle very limited number of cycles in that manner. In short, 100% DoD is not at all preferred for lead acid batteries.

All Capacities are equal, but some are more equal than others

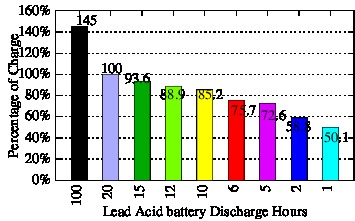

Another interesting parameter is the “name plate” capacity mentioned on the battery. Normally a “120AH” battery gives an implication that, it could give 1A for 120 hours, or 120 A for 1 hour, or 20A for 6 hours or whatever combination of that which gives 120AH as the multiplication output. But, in reality this is not the case. Faster discharging try to reduce the available capacity of the battery drastically. As stated above in the previous section the “name plate” capacity is quoted at C/20 which means at a very slow pace of 20 hours to discharge the battery. Many standard discharge applications using inverters do require much higher discharge rate. Available capacity of a battery could be computed using an empirical law named “Peukert’s law”. The following figure shows the available capacity of a typical Lead Acid battery against discharge time. 100% capacity is stated for 20 hours.

See the interesting fact, if the battery is discharged in 100 hours it could give 145% (actually 45% more than the nameplate) capacity whereas if it is discharged in 6 hours, it could give 75.7% capacity only.

Number of cycles

Total usable cycles of the battery is very much related to the regular depth of discharge. For a regular 80% DoD, a typical battery lasts for around 600 cycles, but if we use 50% DoD, it lasts for around 1200 cycles. There are many telecom batteries which are advertised for 20 years, but they have a rating of 5% to 10% DoD which is ridiculously low(fine prints again). The following graph from windsun.com and Concorde batteries shows the relation between available cycles and Depth of Discharge

Apart from that, there are a few “solar batteries” which could give around 2100 cycles at 80% DoD, like the HuP Solar battery. But they also cost a lot, somewhere between $200 to $300 per KWh

HuP Solar Information

There is a clear disadvantage of the better cycle life and lower DoD. More batteries have to be kept in parallel to store the same amount of electrical energy. That means at 80% DoD, 125% capacity is required whereas at 50% DoD, the requirement would become 200%. If the above mentioned telecom battery is used, the requirement would go more than 1000% !!

So, basically it is a trade-off between capacity, DoD and number of cycles.

That is the story of Lead Acid battery. Let us consider two other types of batteries.

Lithium Ion Battery (Lithium Iron Phosphate)

Like Lead Acid, Lithium Ion is also a family name for, Lithium Cobalt, Lithium Manganese, Lithium Iron Phosphate, Lithium Polymer, Lithium Titanate etc. I am mainly considering Lithium Iron Phosphate for comparison. It has much better cycle life compared to other types of Li-Ion batteries, but a bit lower energy density. Normally Li Ion batteries could handle much better discharge rate compared to Lead Acid batteries. Discharge rate could go more than 2C, that means discharging the battery in 30 minutes. Another advantage of Li Ion battery is that, it has very low dependency on Peukert’s law, that is, even at higher current ratings the battery capacity would not go down like Lead Acid battery. Modern Lithium Iron Phosphate batteries give around 5000 cycles at 70% DoD or 3000 cycles at 80% DoD. The cost has gone down to less than $400 per KWh. Since they have better energy densites, they weigh less and occupy less space compared to Lead Acid batteries.

Specification of Thundersky Lithium Iron Phosphate battery

Sodium Sulphur Battery

Sodium Sulphur could be a very good solution for large scale storage spanning upto MWh range. NGK Insulators of Japan supply these batteries at a price of around $350 per KWh. They are quoted at 2500 cycles at 100% dischange or 4500 cycles at 80% discharge that too at a 6 hour discharge rate. Similar to Lithium Ion, NaS battery has much better energy density compared to Lead Acid, so the weight and volume are also much lower for the same capacity.

Levelized Cost

Let us say that we have to select a battery for renewable energy applications. Since in most cases levelized cost is calculated for a period between 20 to 30 years, we select 9000 cycles which comes very close to 25 years. Assume that the battery has to be discharged in 6 hours. Let us see how these options stand against each other. See the table at the bottom for detailed explanations.

Conclusion

It is very easy to jump to conclusions by seeing the nameplate capacity cost, but actual levelized cost/KWh/cycle is an entirely different story. Cheapest lead acid battery is the costliest to operate in the long run. For small and portable storage applications Lithium Iron Phosphate could be an excellent option. For large installations, Sodium Sulphur could give drastic cost and performance advantages.

Notes

Peukert’s law:

Capacity of Lead Acid battery is computed using the following eqution, as given by An in depth analysis of the maths behind Peukert’s Equation (Peukert’s Law)

T=C x ((C/R)^n-1) /(I^n)

Here n is taken as 1.3 for Lead Acid Battery.

Battery Levelized Cost:

Total cost of batteries to store 1KWh is computed as follows

Multiplier Factor = (1/DoD) x (1/(6 Hours Capacity Factor)) x (Number of times battery has to be replaced to get 9000 Cycles)

6 Hour Capacity Factor is 75.7% for Lead Acid Batteries. Since the capacity of Lithium Ion does not degrade for 6 hours, the factor is taken as 1. For Sodium Sulphur, the name plate capacity itself is stated for 6 hours, so the factor is 1 for that too.

Number of usable cycles for Lead Acid is taken as 750 and 1500 for 80% and 50% DoD respectively.

Total Cost = Cost/KWh nameplate x Multiplication Factor

Levelized Cost = Total Cost / 9000

This is the summary of all these calculations. All prices are in US Dollars only.

Battery Cost Comparisons

| Battery Type |

Cost/KWh nameplate |

% DoD | Usable Cycles |

Number of Replacements |

Multiplier Factor |

Total Cost/KWh | Levelized Cost/KWh per cycle |

|---|---|---|---|---|---|---|---|

| Normal Lead Acid |

120 | 80 | 750 | 12 | 19.80 | $2376 | $0.264 |

| Normal Lead Acid |

120 | 50 | 1500 | 6 | 15.84 | $1900 | $0.211 |

| HuP Lead Acid |

200 | 80 | 2100 | 5 | 8.25 | $1650 | $0.183 |

| Li-Ion | 400 | 80 | 3000 | 3 | 3.75 | $1500 | $0.167 |

| Li-Ion | 400 | 70 | 5000 | 2 | 2.86 | $1144 | $0.127 |

| NaS | 350 | 100 | 2500 | 4 | 4.00 | $1400 | $0.156 |

| NaS | 350 | 80 | 4500 | 2 | 2.50 | $875 | $0.097 |

Excellent Information !

I have been searching various places for the same information .

Thanks …

Have you worked on simulations of draining of batteries ?

Sriram

The salvage value of the lead acid batteries will further bring down the cost of VRLA is it not?

Nimalan

This comparison seems strongly biased against lead acid batteries. There are a couple problems that, in conjunction, make lead acid batteries look far more expensive than they can be:

First, choosing 6 hours for the discharge time seems to be chosen more to handicap lead acid in the comparison, than as typical design criteria. For off-the-grid applications, it makes sense to plan for a 20 hour, or more, discharge time. For grid connected applications, there is no need to discharge any quicker if utility power is available.

Using a more reasonable 20 hour discharge means the discharge capacity factor for all batteries is at unity.

Second, lead acid batteries are readily available for less that 150$/kWh, including shipping.

Third, it would be foolish to purchase only enough lead acid capacity up front that 50% or greater depth of discharge were typically needed. By installing more capacity, not only does the depth of discharge factor improve, but the lifetime number of cycles increases

This comparison seems strongly biased against lead acid batteries. There are a couple problems that, in conjunction, make lead acid batteries look far more expensive than they can be:

First, choosing 6 hours for the discharge time seems to be chosen more to handicap lead acid in the comparison, than as typical design criteria. For off-the-grid applications, it makes sense to plan for a 20 hour, or more, discharge time. For grid connected applications, there is no need to discharge any quicker if utility power is available.

Using a more reasonable 20 hour discharge means the discharge capacity factor for all batteries is at unity.

.

Second, it would be foolish to purchase only enough lead acid capacity up front that 50% or greater depth of discharge were typically needed. By installing more capacity, not only does the depth of discharge factor improve, but the lifetime number of cycles increases. The increase in lifetime cycles per reduction in depth of discharge is so great for DoD below 40% it would be silly not to take advantage of this.

It is not unreasonable to expect 3000 cycles from a typical lead acid battery if DoD is limited to 35%.

Third, there was no comparison of HuP lead acid batteries at 50% depth of discharge or lower. 4100 cycles can be expected limiting DoD to 50%. 9000 cycles at around 25%.

Fourth, (lastly) calculating costs based on the number of replacements needed to reach an arbitrary number of hours (9000 in the case, which isn’t even 25 years, presumably because anything more than 9000 cycles would have required another replacement of the lithium ion batteries, making those noticeably more expensive) really muddied the waters. People aren’t simply going to stop using their batteries right at the end of 25 years. Just do the comparison on cost per time with monkeying around with arbitrary replacement periods.

.

So for 50% DoD at 20 hour discharge a HuP lead acid battery comes out to:

$200/kWh÷50%÷4100 cycles = $0.0976/kWh-cycle

…suddenly lithium ion does not look so cheap.

.

What about a more appropriately sized normal lead acid? For example 35% DoD, discharge designed for 20 hours:

$120/kWh÷35%÷3000 cycles = $0.1142/kWh-cycle

….easily less expensive than lithium ion.

The price per kWh-cycle is even better when the DoD is further reduced. The only time this wouldn’t make sense is if there was an important weight limit or restrictive size limit…..but most people who I stall solar, have the room to do so and thus plenty of room for low cost lead acid batteries.

@Ben Griffin,

I partially agree with you. The calcluations you have shown for Lead Acid looks really good. However we need to consider a few more points.

* Lead Acid is a very mature technology and not a lot is happening in that space whereas lots of research is going on in newer technologies using Lithium, Sodium and Aluminium both by research institutions and commercial organizations.

* In standard telecom and UPS scenarios weight of the Lead Acid battery may not matter. But, in many residential situation size and weight could matter. Name plate capacity of Lead Acid is around 40Wh/kg, if you consider 50% DoD, effectively it could become 20Wh/kg. Consider that with Tesla PowerWall which got released a few days before. The spec says that it is a 10KWh battery weighing 100kg for USD 3500. If we want to use a Lead Acid battery with 50% DoD, it would easily weigh around 500kg.

* We need to also consider the environmental pollution factor of Lead as well.

6 hour discharge cycle used.

The discharge time for calculation is entirely use case dependent. In my original article, I mentioned 6 hour discharge cycle for each battery. This is considering a typical solar electrification scenario in many places especially in rual India without grid electricity. The peak power demand from the battery is for around 4 to 5 hours, typically from 6pm to 10pm and in the day time the battery is not loaded due to the availability of solar electricity. This is a normal use case for residential or small business in those places. Considering this fact, the useful capacity would be around 70% of the nameplate.

Only just recently(2017) came across lead crystal batteries at a comparable cost to lead acid batteries, they can be discharged to 100% for 1800 cycles and are easy to obtain, they have similar charging characteristics to the old lead acid batteries. I think these batteries are going to be a really good replacement for the old lead acid technology